Importing plywood is critical to the U.S. construction industry, especially in the housing market. However, it has also become a highly taxed import and supplier markets are shifting because of it. Continued success will depend on keeping up with changes and adapting your business model to meet them.

Key Takeaways:

Learn to navigate the regulations involved in importing plywood to the United States as a composite wood product.

One of the first things you should understand about importing plywood is that despite its name, it is not considered a timber product regulated by the U.S. Department of Agriculture. Plywood is considered a composite wood or engineered wood product.

The process by which the panels are created uses resins and glues that are regulated by the Environmental Protection Agency (EPA). While the USDA may track the imports, it’s the EPA you need to keep happy.

Related imports tracked by the USDA’s Foreign Agriculture Service include:

These fall under a few different Harmonized Tariff Schedule (HTS) headings, but the most relevant are 4410, 4411, and 4412.

The majority of plywood panels can also be imported to the U.S. without a timber permit. There are exceptions based on the type of timber used to create the panels in the first place.

This is the reason that plywood is also commonly used as a wood packing material for transporting other timber that is subject to USDA regulation. It can be used in the creation of crates, pallets, and skids.

If you are looking to import other kinds of timber, check out our article, “Importing Wood to USA”.

Worried about the Strict Regulations? Ask Our Experts.

Get One-on-One Expert Consulting To Personally Guide You.

Whether we’re discussing plywood or OSB, the U.S. remains the top global importer. However, its top suppliers for plywood and related composite wood products have shifted in recent years.

For instance, despite China’s status as the top exporter of plywood, high tariff rates imposed by Section 301 since 2018, have steadily cut down U.S. import numbers. Likewise, products from Russia, once a top supplier of hardwood plywood imports, have been subject to a 40% ad valorem tariff since that nation’s invasion of Ukraine in 2022. The result? A 70% decline in import value.

Let’s take a look at the top suppliers since then.

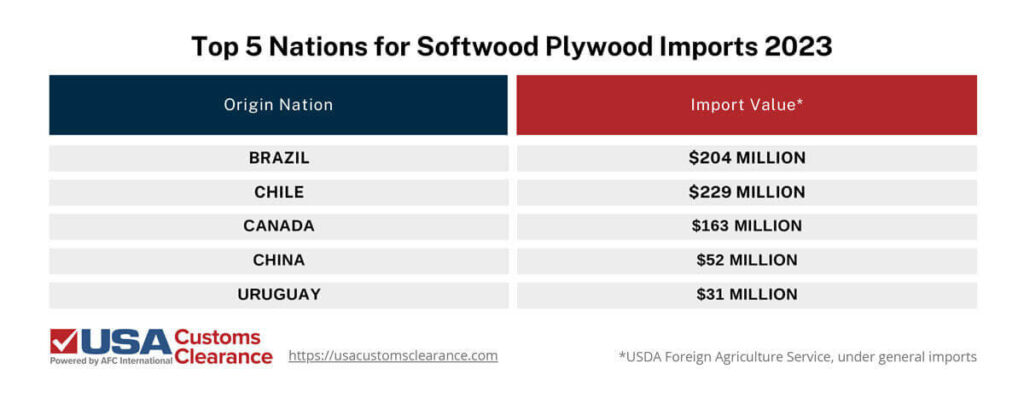

For softwood plywood, the list looks different, but there are some common players.

You’ll notice that China still makes the top five list of suppliers at this time, but realize the export value of their plywood to the U.S. has been dropping. Between 2020 and 2023, their total import value into the U.S. fell roughly 50%.

Although they aren’t the only country to see a decrease, theirs has been a consistent downturn rather than a bad year here or there.

When you narrow it down to OSB, currently the most popular for widespread home construction and significantly less expensive than pressed panel plywood, Canada practically holds a monopoly. In 2022, over 91% of imported OSB came from there.

The United States-Mexico-Canada Agreement (USMCA) has played a large role in increasing trade in that regard.

Before you finalize where you plan to source from, also consider the costs that you may face.

As mentioned, composite wood products generally fall under three HTS headings, each with its own tariff range.

Changing political climates continue to impact trade agreements. As mentioned, nations such as China and Russia, while still having the resources and ability to produce materials, have harsh tariffs levied against plywood and related materials.

Section 301 tariffs imposed against China add a 25% rate on top of any currently applicable tariffs for the HTS headings we’ve listed. Since 2019 (and confirmed again in 2023) there have also been antidumping/countervailing (AD/CV) duties imposed on hardwood plywood from China specifically.

Related: How to Import OSB and Plywood From China (If You Dare)

Then there’s Russia (and Belarus) and their vast stores of prized hardwood birch plywood. It’s not a sanctioned product, so you can still import this and other composite wood products. Tariffs on Russian plywood and related products range from 20% to 50% with certain items subject to a per/kg tariff in addition to an ad valorem one.

Meanwhile, imports from Canada, another high-producing supplier, have been affected by Department of Commerce investigations into anti-dumping and countervailing in regard to softwood lumber. While plywood is not technically a lumber product, it’s a likely target of the new White House administration’s vocal call to further tax Canadian imports.

In the meantime, plywood and other composite woods can be imported into the U.S. from Canada duty-free as long as USMCA rules of origin are met.

Finally, you will need to calculate for a 10% tariff rate. Tariffs for China are much higer, and they could increase in the future. These tariffs were put in place April 2025 in an effort by the government to combat trade imbalances.

Of course, none of these things have stopped imports entirely, but they have made it necessary for importers to investigate new markets.

The good news is that the regulations to import hardwood and softwood plywood are the same, as well as those of other engineered wood products. With that out of the way, you just need to focus on where to source from.

If you are trying to become a plywood wholesaler and wish to offer a wide variety of products, then it may be best to source from a country like Canada. The nation is a top supplier for all kinds of engineered wood products.

For bulk imports of specific plywood products, more research is needed. As an example, you can refer to the data tables used earlier to see the top suppliers for both hardwood and softwood plywood imports.

Additionally, Canada, as well as Vietnam, and Chile, are members of the CPTPP (Comprehensive and Progressive Agreement for Trans-Pacific Partnership). This has allowed them to experience tremendous growth in their manufacturing and export capabilities since signing in 2018. While no longer a member of the CPTPP, the United States import industry has still managed to benefit from their improvements.

Unlike other timber and timber products, plywood does not require an Animal and Plant Health Inspection Service (APHIS) import permit from the USDA. This permit, PPQ form 585, only applies to timber and timber products that may be subject to Plant Protection and Quarantine (PPQ) procedures.

PPQ procedures are determined by the International Standards for Phytosanitary Measures (ISPM). Plywood is exempt from the ISPM’s phytosanitary certificate requirement because of the manufacturing process used to create it.

If the lumber used to create the plywood comes from protected timber sources, you may need to file for a CITES permit. As an organization, CITES works to regulate the trade of protected species through an animal, timber, and timber product import permit. CITES is an international organization and member nations follow regulations voluntarily.

Many nations use CITES regulations to frame their own national conservation laws. Participating nations manage their own enforcement of regulations, permits, and certificates.

When importing plywood, your export partner needs to provide the scientific name of the tree species used. You must then check that name against the database of endangered trees maintained by CITES.

The species name must be provided on at least one of these documents:

Should the species of timber used in the plywood come up in the CITES database, further documents are needed

Related: Importing Rosewood

Worried about the Strict Regulations? Ask Our Experts.

Get One-on-One Expert Consulting To Personally Guide You.

Administered in part by APHIS, the Lacey Act is focused on fighting and preventing the illegal traffic of wildlife, fish, and plants. Importers working with goods related to any of those categories must submit a Lacey Act Declaration.

Plywood classified under HTS code 4412 requires importers to file a Lacey Act Declaration.

A Lacey Act Declaration must include information on:

While there are some exemptions, these should be discussed with an experienced and licensed customs broker familiar with wood and wood product imports.

We have established that the USDA does not heavily regulate plywood. From an agricultural standpoint, imported plywood does not present a biological threat.

Plywood regulations are instead based on the chemicals and emissions involved in their manufacture. The EPA has set standards in place for plywood as a composite wood product created using formaldehyde. These standards were created with the Formaldehyde Emission Standards for Composite Wood Products Act. Commonly known as Title VI of the Toxic Substances Control Act (TSCA), it began enforcing new regulations in March 2019.

Since then, various updates have been made and publicized in the Federal Register These regulations are specifically enforced on:

Anyone importing, distributing, or selling these products must comply with TSCA regulations. Importers must take care to source products from manufacturers meeting emission requirements. The EPA has provided a compliance checklist for importers to complete before starting the shipping process.

Once everything on the checklist is confirmed, importers certify that it meets standards by signing a TSCA section 13 certificate. For small businesses or new importers who may need help, the EPA provides some compliance assistance.

For new importers looking to fully dive into the plywood industry, it's recommended you contract or at least consult with an experienced customs broker. If shipments come into port and are found to be out of compliance, the EPA can file penalties of up to $37,000 per day.

A conversation with a customs broker that may cost you a few hundred is a worthwhile investment in that scenario.

In an effort to prevent pests and invasive species from entering the country, chemical or heat treatments to fumigate shipments are often done. The manufacturing process to produce plywood submits it to both high heat and pressure which makes fumigation unnecessary.

The sheets that make up plywood are glued and pressed together under hydraulic presses using immense pressure - as much as 200 psi’s worth. At the same time, the sheets are heated to about 300°F. This far exceeds the USDA’s requirement for heat treatment, which only requires temperatures of 133°F.

Manufacturing plywood removes any pests or other invasive lifeforms in the wood that would otherwise be removed by chemical or heat processes. It is because of this process that plywood is not as heavily regulated as other types of timber and timber products that enter the U.S.

Worried about the Strict Regulations? Ask Our Experts.

Get One-on-One Expert Consulting To Personally Guide You.

If you’re looking to import plywood into the U.S., choose a partner that can help you maximize potential profits and avoid the pitfalls of harsh penalties and fines.

USA Customs Clearance has Experienced and Licensed Customs Brokers ready to talk with you 1-on-1 and advise you on important documents needed for import.

Among our various services, we also offer:

Get in touch with us today at (855) 912-0406 and make importing plywood to the USA your next great business venture.

Copy URL to Clipboard

Copy URL to Clipboard

Add your first comment to this post